Planer-made toolings are a popular choice for precision oriented applications. These types of press brake toolings come in long segments that have been cut into shorter lengths which can then be labeled and reassembled with even more precision to create an even narrower tolerance range than before!

Planer made tooling

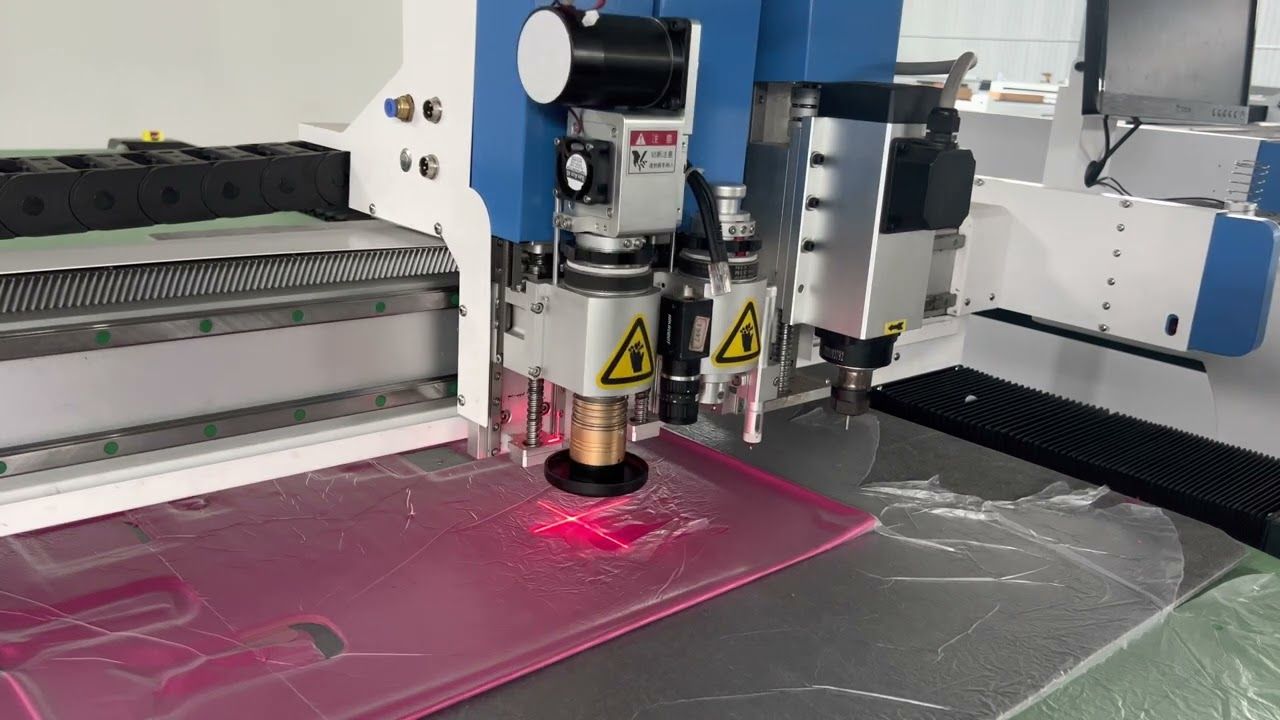

Press brake tooling is available in different designs and specifications. In general, press brake tooling is custom-made from steel billets and machined on large milling machines, planers, and grinders. Tool steel is often quenched and induction hardened, which improves its lifespan. Then, the tooling is fitted onto the press brake.Precision-ground tooling can be made to precise tolerances of 0.0002 in. or 0.004 in.; however, planer-made press brake tooling can range in accuracy from 0.002 in. To achieve this, precision ground press brake tooling has a greater tolerance than traditional planer tooling. While this is an option that saves money, it also poses a challenge.

Standard punch

The Standard Punch is a basic tool for bending thick material profiles. It is the most common type of punch for everyday bending operations. Its high strength and ability to withstand high loads make it ideal for longer bending lines. While not as widely used as the Acute Punch, the Standard Punch is still an essential tool for many industries.When selecting a press brake tooling set, it is important to consider the tooling for the part to be curved. The maximum bending length is often the same as the maximum tooling length. For example, if a part needs to be bent deep inside the throat, it will require a tooling set with a higher bending length than the standard size.

2V dies

There are two kinds of press brake dies: V-dies and 2V-dies. Each has a different bend angle and is used for different types of materials. A V-die usually has one V-shaped groove, while a 2V-die has two parallel grooves of varying widths and angles. Both types of press brake dies are suitable for bending different types of sheet metal.A 2-V die can be changed easily on a press brake by simply dropping it on the Quick Change Die Rail. This type of die is used for AMERICAN-style press brakes and the AMADA-style press brake. There are also 4-V and acute-angle V-Dies.

Polyurethane tooling

Urethane press brake tooling is used to shape steel, aluminum, and other metals. It has the ability to produce unique shapes and a smooth, unmarked finish. In addition, it is very affordable. Here's how it works: Urethane tooling has two main parts: the die pad and the punch tip. The die pad provides the necessary resistance against the punch, and it sits inside a retaining box. The retaining box provides horizontal support for the die pad during bending. The retaining box is often complemented with deflecting bars.Urethane tooling is very versatile, and it can be used for a variety of manufacturing processes. It can be used to make a variety of shapes, including complex profiles. Its natural crowning ability makes it an excellent choice for bottom bending press brake applications. However, it does not work well for air bending.