One of the best benefits of CNC machining is that it allows for the production of custom machined parts. The machining service ensures that the part manufactured meets a customer’s specifications. Furthermore, custom machined parts production is currently made to be quite fast, and customers can receive the parts ordered in a matter of days after the agreement has been set. Fast production of custom-made parts is one of the reasons why custom machined parts are thriving. Below are several other reasons why custom machined parts are successful.

The custom machined parts success

1. CAD modeling

CAD modeling is also referred to as Computer-aided Design. It is a crucial part of a component’s design process. CAD modeling ensures that one’s idea is brought to life through the digital world. Through CAD modeling, manufacturers can grasp a customer’s idea of a custom part. Thus, ensure they transform the idea into life. Furthermore, CAD modeling ensures that the production of custom-made parts is successful.

2. Unique parts

One of the reasons why custom machined parts are successful is because they are unique. It is because clients draw up their unique product design and offer the design to manufacturers to produce. Furthermore, the custom machined parts are not like any generic parts; they do not exist in the market. They can also involve new part innovations in the market. Thus, the custom machined parts are the only of their kind in the market.

3. Fast production process

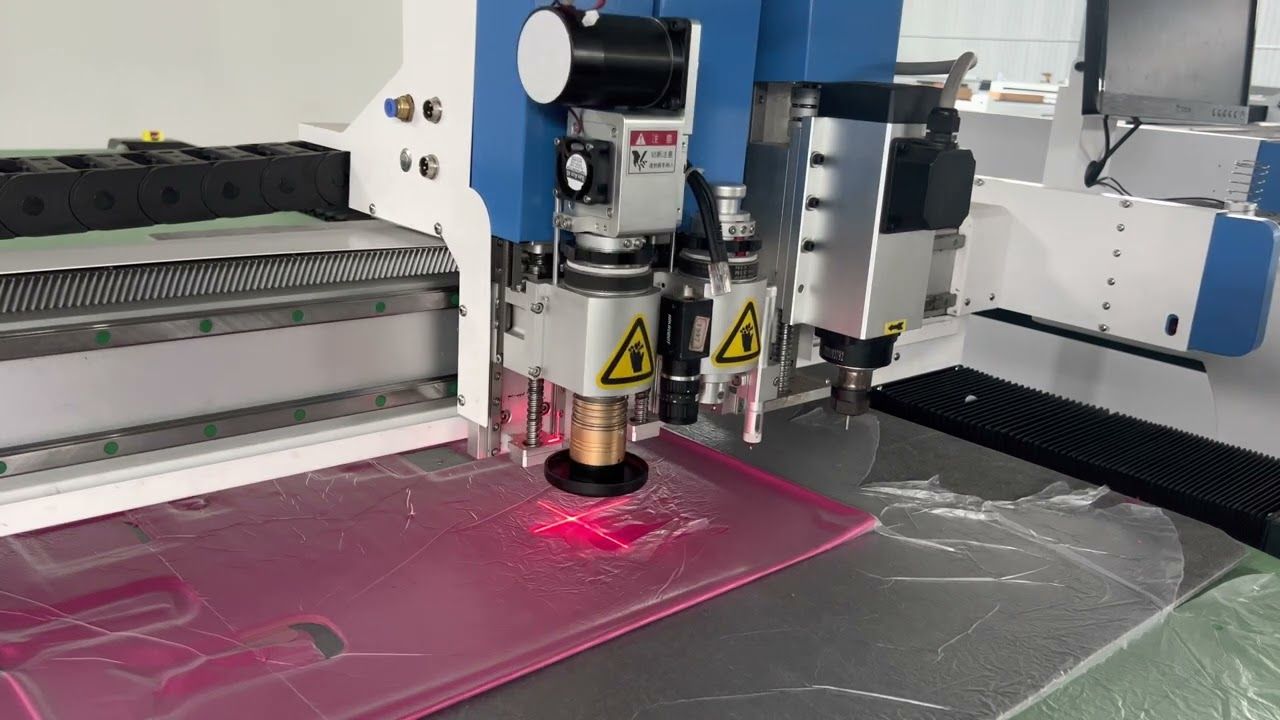

Custom machined parts are made using the latest CNC machining technology innovations. The machining process allows for fast manufacturing procedures. Thus, customers can receive their custom-ordered parts in a matter of days. Custom machining is almost the same as ordering a part from a catalog. Therefore, one of the best reasons the custom machined parts are successful is that clients can receive quality parts in the shortest time possible.

4. Use of various machining processes

The manufacturing of custom machined parts is not limited to only one process but several. The several techniques include; CNC turning, CNC milling, EDM, and so many more. Therefore, clients are usually guaranteed that they can pick whatever method suits their project best.

5. Reasonable price

One of the best reasons why custom machine parts are so successful is because of their affordability. The latest technology innovations in machining services ensure that the part is produced with little material waste. Furthermore, parts are made to the client’s exact specifications. Thus, the custom machine parts are pretty affordable.

6. Additional features

Another reason custom machined parts are successful is that it allows for the change of standard parts into custom parts. It involves the addition of new features to standard parts. The addition of features can help in making a part more personalized. For example, a standard adapter can be converted to a custom adapter by textual engraving.

7. Available in small quantities

Custom machined parts do not have to be attained through mass production. Therefore, CNC manufacturers can produce custom-made parts in only the amount needed. Thus, the custom-made parts can be available in small quantities.

Conclusion

Technological innovations in machining services allow for the production of custom machined parts. The Custom machined parts are currently successful for several reasons, as can be seen from above. Furthermore, the presence of modern technologies ensures quick production procedures.