ASTM A500 remains an establishment in structural design, offering standard details for cold-shaped, welded, and seamless carbon steel essential tubing. Serving as a signal of top-notch quality and dependability, ASTM A500 presents specialists, modelers, and engineers with a relied-on system for planning and building various designs.

With its versatility in accommodating numerous styles and sizes, ASTM A500 tubing reveals substantial software throughout construction tasks, infrastructure improvement, mechanical assemblies, and architectural factors. The intrinsic energy and durability of ASTM A500 make it a go-to preference for helping heavy hundreds and enduring hard environmental situations.

Manufacturing Method Of ASTM A500 Tubing

Right here is the detailed manufacturing process of ASTM A500, from raw material choice to product inspection.

Raw Material Selection

The technique starts with selecting fantastic steel, commonly low-carbon or medium-carbon metallic. The selected steel ought to meet the chemical composition necessities designated by way of ASTM A500, which includes limits on elements along with carbon, manganese, phosphorus, sulfur, and copper. This feature is critical as it immediately affects the mechanical homes and overall performance of the finished tubing.

Steel Coil Preparation

As soon as the steel is selected, it's processed into coils or sheets. These coils are then uncoiled and flattened to create a uniform starting fabric for the tube formation. The metallic strips are inspected for floor defects, thickness consistency, and width accuracy. Any imperfections or inconsistencies can affect the subsequent production stages, so quality control at this factor is critical.

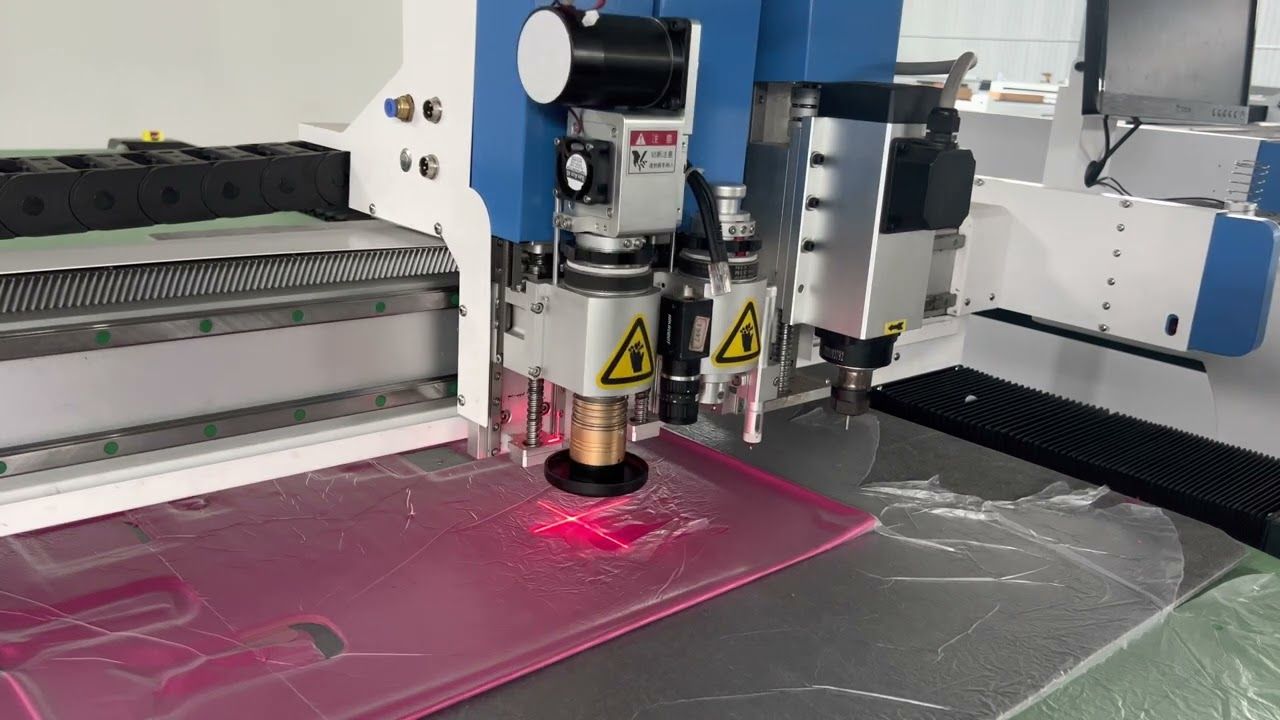

Forming The Tube

The subsequent step entails forming the flat metal strip into a tubular form. That is typically performed using a system referred to as roll forming, in which the steel strip is surpassed via a chain of rollers that regularly bend it into a spherical, square, or rectangular tube form. The roll-forming system is cautiously controlled to maintain the desired dimensions and form of the tubing.

Seamless Welding

Inside the seamless welding framework for ASTM A500 tubing, the edges of the molded metal strip are warmed and combined. That is normally helped out using electric opposition welding (ERW) or enlistment welding. ERW warms the edges through the utilization of electric resistance, while acceptance welding utilizes an enlistment loop. Each technique produces robust, steady welds, ensuring the integrity and energy of the tubing.

Cooling And Sizing

Post-welding, the tubing goes through cooling, for the most part using water splashes. Controlled cooling is fundamental to assuage any thermal stresses caused during welding and to guarantee the weld's integrity. Once cooled, the tubing is handled via sizing rolls that refine the tube dimensions to meet precise tolerances. This step is critical for achieving the suitable outer diameter and wall thickness required by using ASTM A500 specs.

Cutting to Length

The continuous lengths of tubing are then cut to the favored lengths. This is commonly performed using excessive-pace rotary saws or flying saws that reduce the tubing to unique lengths because it moves alongside the production line. Lengths are usually standardized, however, custom lengths can also be produced primarily based on particular client necessities.

Surface Finishing

Surface completion of ASTM A500 tubing complements its durability and look. Common methods include pickling and oiling, where the tubing is dipped in an acid solution to take away scale and rust, and then covered with oil to prevent further corrosion. Galvanizing is another alternative, coating the steel with a layer of zinc for improved corrosion resistance, making the tubing suitable for diverse environmental situations.

Marking And Packaging

Once the tubing has exceeded all pleasant manage assessments, it is marked with relevant information consisting of the manufacturer's call, grade, specification variety (ASTM A500), and warmth range. This marking guarantees traceability and compliance with industry standards. The tubes are then bundled, normally using steel straps or twine, and prepared for shipping. Shielding quit caps will also be implemented to prevent damage to the ends during transportation.

Conclusion

The manufacturing technique of ASTM A500 tubing is a comprehensive and meticulous method concerning several crucial steps, from raw material choice to product packing. Each stage is designed to make certain that the tubing meets stringent specs for structural applications, providing important electricity, durability, and reliability. This designated manner enables ASTM A500 tubing to be a preferred choice for an extensive range of construction and structural tasks.