Every business with tangible goods grapples with the persistent challenge of packaging their products in a way that is efficient, cost-effective, and ensures their merchandise remains undamaged. This is where the marvel of shrink wrap machines comes into play, offering businesses an effective solution that addresses these challenges head-on. Visit the https://www.keeptoppackaging.com/products/shrink-wrap-machines/ to learn more.

Navigating Packaging Challenges

Traditional packaging operations often involve an extensive amount of manual labor, proving to be time-consuming and expensive. The process of wrapping, sealing, and labeling each product is not only labor-intensive but also susceptible to human errors, potentially leading to inconsistency in packaging quality or worse, product damage. As businesses scale and product volumes grow, manual processes can become a significant roadblock, hindering productivity and efficiency.

The Shrink Wrap Machines Revolution

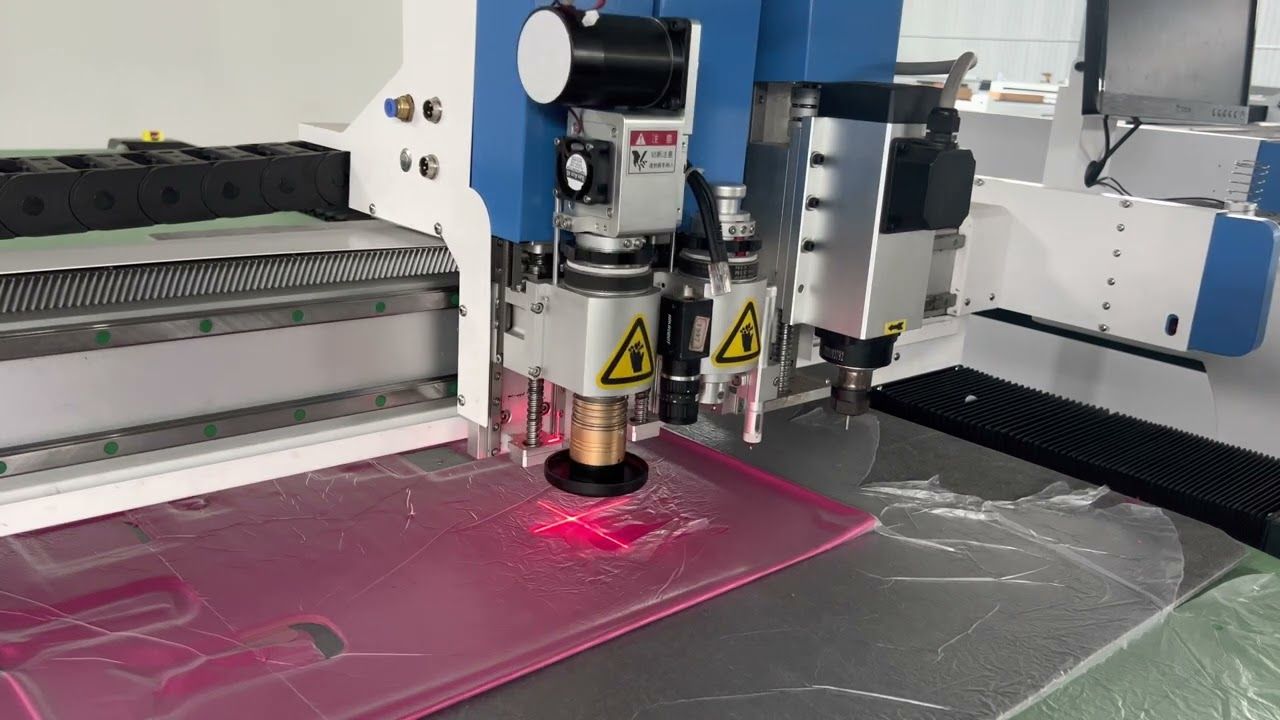

Enter the shrink wrap machines - game-changers in the packaging industry that can dramatically reduce labor time and operational costs. The process is automated: a product is enveloped in a plastic film, which is subsequently heated causing it to shrink and fit snugly around the product. This efficient procedure reduces the need for manual labor, thereby slashing labor costs and time significantly.

Moreover, the cost savings don't just end with labor expenses. Shrink wrap machines also minimize material waste, resulting in additional savings that businesses can channel towards other critical areas such as R&D, marketing, or customer service.

Guarding Product Integrity

Shrink wrap machines don't just boost efficiency; they also play an instrumental role in preserving product integrity and averting damage during transit. The plastic wrap, which shrinks to fit securely around the products, acts as a protective shield against moisture, dust, and other environmental factors.

This advantage is especially beneficial for businesses dealing with fragile items or products that require protection from the environment. Ensuring that products reach their customers in perfect condition can significantly improve customer satisfaction and enhance brand reputation.

One Machine, Many Sizes and Shapes

Shrink wrap machines are incredibly versatile, capable of handling products of different sizes and shapes, from small components of electronic devices to bulky household appliances, and even items with irregular shapes. The variety of machines available, from compact desktop models to massive industrial versions, means there is a suitable option for every business's unique requirements.

Harnessing the Full Potential of Shrink Wrap Machines

Effective implementation of shrink wrap machines is crucial to fully reaping their benefits. This includes choosing an appropriately sized machine, using the right type of shrink wrap film, and ensuring staff are properly trained to operate the machines safely and efficiently.

In addition to this, regular maintenance checks are crucial to keep the machines operating smoothly, preventing potential downtimes that could disrupt the packaging process. It's also important to ensure the machine's temperature settings align with the type of film being used, as this directly affects the quality of the shrink wrapping.

Wrapping It Up

In conclusion, shrink wrap machines can dramatically improve packaging operations and product quality. By slashing labor costs, safeguarding product integrity, and offering versatile solutions for different products, these machines offer businesses a distinct competitive advantage.

In the final analysis, the use of shrink wrap machines can not only enhance packaging operations but also significantly improve the end customer experience, as they receive products that are well-protected and in excellent condition. Therefore, the decision to invest in shrink wrap machines can be a strategic one, potentially leading to substantial long-term benefits.