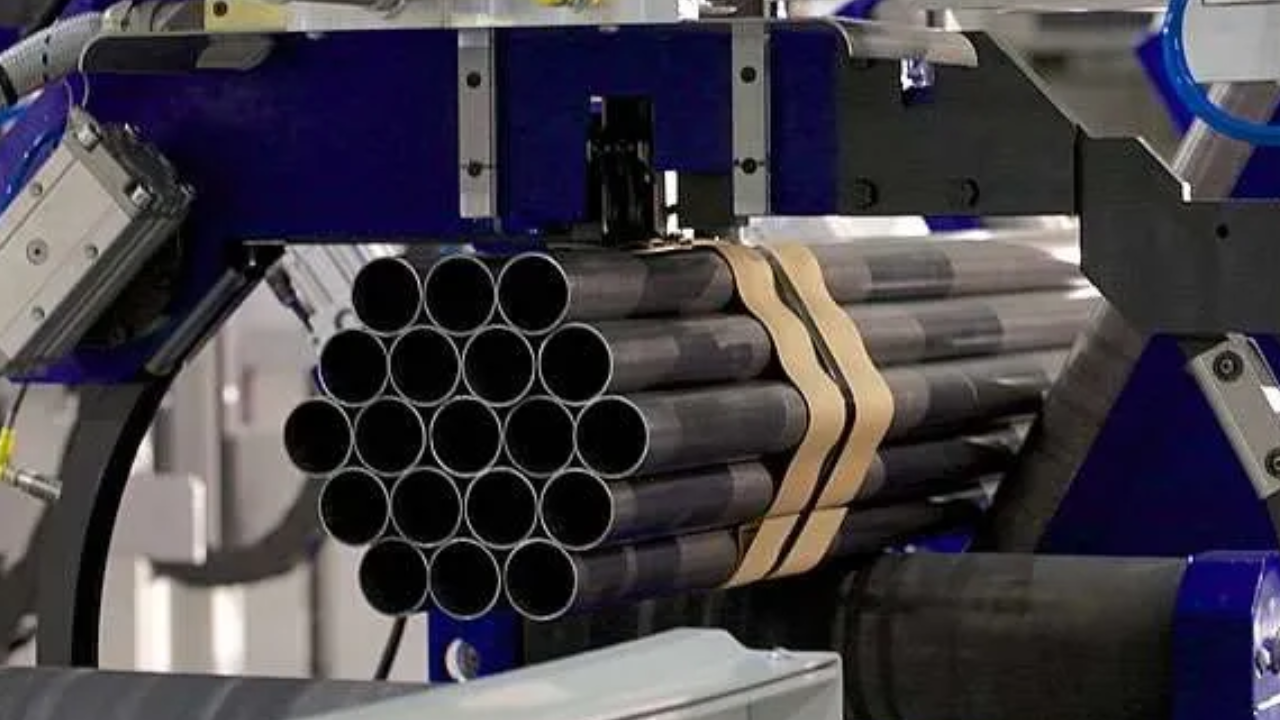

Steel tubing is a critical component in various industries, renowned for its strength, versatility, and wide-ranging applications. Composed of durable steel alloys, tubing comes in various shapes, such as round, square, and rectangular, each serving specific needs in construction, manufacturing, and infrastructure.

One of the key advantages of steel tubing lies in its structural integrity and resistance to external forces, making it ideal for applications requiring robust and reliable support. Seamless steel tubing, manufactured through extrusion, offers a continuous and uniform structure, making it suitable for high-pressure environments.

Fluid transmission, structural frameworks, equipment components, and many other uses are for steel tubing. Steel Tubing is an important material in modern construction and engineering projects due to its capacity to withstand extreme circumstances, corrosion resistance through coatings such as galvanization, and adherence to strict industry standards.

Corrosion Protection Methods for Steel Tubing

Steel tubing, while known for its strength and adaptability, is prone to corrosion when exposed to external factors. Corrosion can jeopardize the structural integrity and durability of steel tubes. As a result, employing efficient corrosion prevention solutions is critical to ensuring longevity and reliability. This article investigates numerous corrosion protection procedures used for steel tubing, going into the benefits and drawbacks of each method.

Galvanization

Galvanizing involves applying a layer of zinc to steel tubing. Hot-dip galvanization and electro-galvanization are two possible processes. Hot-dip galvanization immerses the steel in molten zinc, whereas electro-galvanization coats it with zinc using an electroplating technique. Zinc acts as a sacrificial anode, corroding preferentially and protecting the underlying steel.

Galvanized steel tubes are highly corrosion-resistant and ideal for outdoor applications like fences, buildings, and maritime projects. Galvanization can change the appearance of the tubing, and the thickness of the zinc coating affects the level of corrosion resistance. Regular maintenance and inspections are recommended to treat any coating deterioration.

Painting and Coating

Steel tubes can be protected from corrosion using a variety of paint and coating methods. This entails applying multiple layers of protective coatings, including primers, intermediate coats, and a topcoat. Painting and coating create an aesthetically pleasing appearance while protecting against environmental influences.

Epoxy, polyurethane, and enamel paints are popular options for protecting steel from moisture and corrosive chemicals. The coating's efficiency is determined by its application method, thickness, and material quality. Regular inspections and maintenance, including recoating as needed, are vital for long-term protection.

Powder Coating

Powder coating is a dry finishing technique in which a powdered polymer is electrostatically applied to the steel tube. The coated tubing is then oven-cured to give it a long-lasting and consistent finish. Powder coating produces an appealing and long-lasting finish with exceptional corrosion resistance.

It comes in a range of colors and provides both protection and aesthetic customization. Surface preparation is critical for the performance of powder coatings. Before applying the coating, all impurities or rust should be removed from the steel surface. Powder coating may necessitate a more regulated setting for the best results.

Cathodic Protection

Cathodic protection makes use of sacrificial or impressed current systems. Sacrificial anodes, usually constructed of zinc or aluminum, are attached to the steel tubing and corrode in place of the steel. In impressed current systems, an external current is applied to the steel to prevent corrosion.

Cathodic protection prevents corrosion by regulating electrochemical processes on the steel surface. It is commonly utilized in submerged or buried steel tubing applications, such as pipelines. Cathodic protection systems must be properly designed and monitored to ensure their success. Sacrificial anodes may need to be replaced regularly, whereas current systems require continual maintenance.

Stainless Steel Tubing

The stainless steel tube has natural corrosion resistance because of its composition, which includes chromium, nickel, and other alloying components. This alloy forms a passive oxide coating on its surface that shields the steel against corrosion. Stainless steel tubing is highly corrosion-resistant and requires no additional coatings.

It is suitable for applications that regularly expose workers to corrosive environments. Even though stainless steel is corrosion-resistant, it may not be suitable for all applications. When selecting stainless steel tubes, keep costs, fabrication requirements, and the unique corrosive environment in mind.

Summary

Protecting steel tubes from corrosion is critical to guaranteeing their resilience and lifespan in a variety of settings. Each corrosion protection approach has advantages and drawbacks. Implementing efficient corrosion prevention techniques improves the performance and longevity of steel tubing in a variety of engineering and construction settings. Regular inspections and preventative maintenance are still necessary to maintain the efficiency of these corrosion control measures over time.